Printed circuit boards are the lifeblood of the electronics industry. With so many parts on a printed circuit board assembly, though, much can go wrong. A poor soldering job, low quality components, or degraded metal plating can cause the entire assembly to malfunction. That’s where a good printed circuit board...

News

Understanding Brush Plating

Brush electroplating, also known as selective plating or spot plating, allows you to plate an entire item, or a specific part of that item, using a brush saturated with plating solution. It offers greater portability than tank plating, minimal masking requirements (and sometimes none at all), and often requires less...

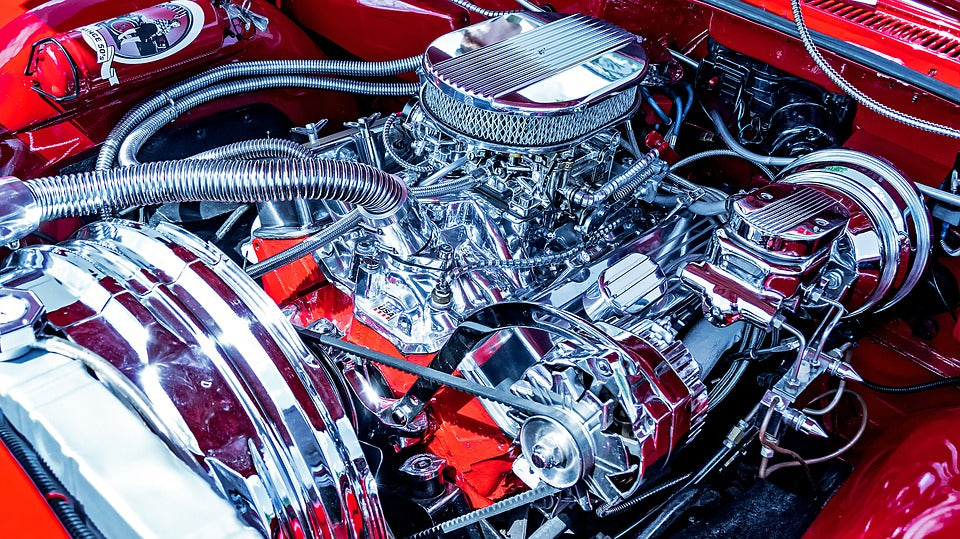

Why Choose Chrome Plating?

Chrome plating is the process of electroplating a layer of chrome onto a base metal. (Pixabay / code83) Chrome plating is used for: Adding a decorative finish Providing corrosion-resistance Making an object harder and more durable The basic steps of chrome plating include the following: Cleaning the substrate to remove all...

Improving Electrical Conductivity

There are many reasons for electroplating. It can enhance a component’s strength, solderability, and corrosion-resistance. Electroplating can also improve the electrical conductivity of a base material. (Pixabay / PublicDomainPictures) Electrical conductivity measures how well a material accommodates the movement of an electric charge. Conductivity values are generally conveyed as “percent IACS”...

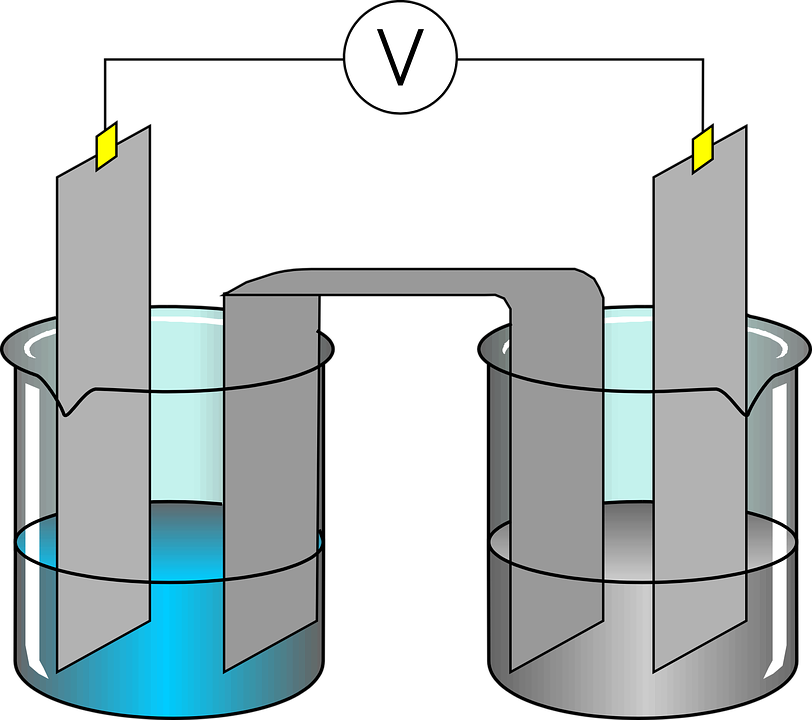

Electrocleaning Methods

Before you can electroplate an item, you need to electroclean it. There are a few ways to do this: Reverse-current electrocleaning (anodic) Direct-current electrocleaning (cathodic) (Pixabay / Clker-Free-Vector-Images) Here’s a closer look at both processes. Reverse-current electrocleaning With this process, you dissolve and clean the metal surface at the same time,...