Industrial Plating Services

Industrial Gold Plating Experience:

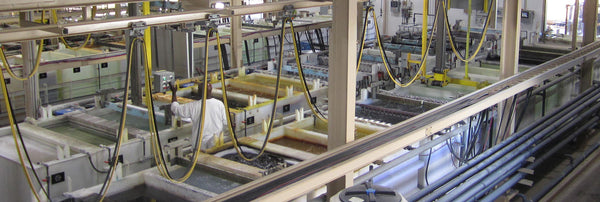

Gold Plating Services is a 30-year-old industry leading company that has unique experience in the industrial, scientific, and technical plating field. We have the technical expertise and proprietary processes necessary to meet the specific requirements of these fields.

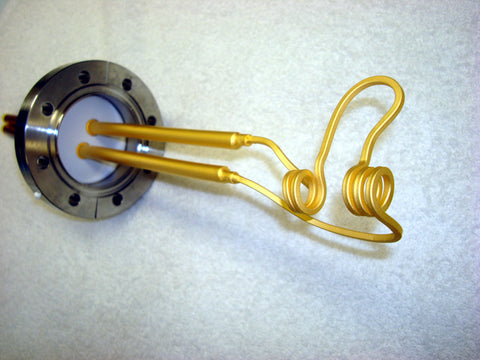

Gold Plating Services has extensive experience performing MIL-Spec plating for aerospace, military, defense, medical, cryogenics, research & development, fuel cells, and electronics.

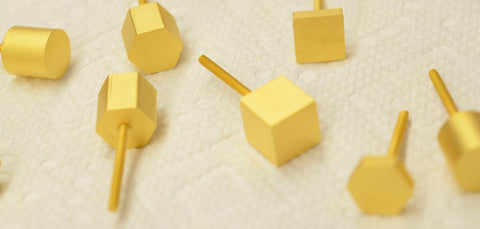

Gold can be plated directly onto a base metal using the electro-chemical process called “electroplating”. Some metals may require a layer of nickel to be applied prior to plating with gold to allow adhesion or provide a diffusion barrier. Other applications may need the gold applied directly to the substrate; this is frequently found in the cryogenic field. The purpose for gold plating includes conductivity, decoration, corrosion protection, reflectivity, bioavailability, and wire bonding.

Gold is frequently used for conductivity in place of silver due to its tarnish resistant properties. Gold is also impervious to most chemicals making it the preferred choice in respect to corrosion protection.

For an item to be considered “gold plated” it must have a minimum thickness of 7 microinches, which is typically done for decorative purposes. Hard gold (Type I & II) can be plated to around 100 microinches (2.5 microns) max. It is the most common choice for decorative finishes or items that require a durable finish. Soft gold (Type III) can be plated to virtually any thickness and is most commonly used for scientific plating. Request a quote today.

MIL spec Plating

At Gold Plating Services we provide metal finishing and gold plating for many different customers for many different reasons. Many of our customers want decorative gold plating and rely on our expertise to provide them with a type and thickness of gold plating that will best fit their purposes and budgets. We have the experience and expertise to advise them on their options. Other clients use standard specifications that define many important aspects of the plating process. For those who aren't sure of exactly what will work best for them we may suggest a specification process that will define the results they need. We specialize in plating a 24Karat gold to a specific MIL-Spec. (MIL-G-45204-C - recently superseded by MIL-DTL-45204D see below). Plating gold to these specifications insure that the final product will meet strict purity, thickness, and hardness standards. These specifications also mandate other factors such as undercoating, adhesion, and solderability. The specifications also reference other MIL and ASTM standards and verification tests. Testing is available upon request (additional pricing applied). We apply Mil-Spec plating to items for the aircraft, medical instrumentation industry, and electronics industry. In some cases we are applying a 24K gold plate to various grades of stainless steel and in others we are plating onto copper, aluminum, or brass alloys.

New MIL-DTL-45204D Gold Plating Specification. The U.S. Army Research Laboratory has developed a new specification that supersedes the MIL-G-45204C, (dated 7 June 1983), specification referenced above. The new specification is MIL-DTL-45204D (dated 29 June 2007), is 24 years more current, and addresses questions not adequately covered by the old specification. The classifications by Type, Grade, Purity vs. hardness, and Class are similar to the old spec, however the new specification includes standardization references to non-governmental and international (ISO) agreements.

The new specification also has expanded quality control, testing, and packaging procedures. We have this document available as a PDF file. Click Here

Specifications:

- MIL-G-45204

- AMS 2422

- ASTM B488

Purity:

- Soft Gold (Type III) up to 99.9% minimum purity.

- Hard Gold (Type I and Type II) 99.7% minimum purity.

Gold Plating Services to MIL-G-45204

-

Type I – 99.7 percent gold minimum

-

Type II – 99.0 percent gold minimum

- Type III – 99.9 percent gold minimum

- Grade A – Knoop hardness 90 max

- Grade B – Knoop hardness 91-129, incl.

- Grade C – Knoop hardness 130-200, incl.

- Grade D – Knoop hardness 201 and over.

If the hardness grade for the gold coating is not specified, Type I shall be furnished at hardness Grade A (90 Knoop max) and Type II shall be furnished at hardness Grade C (130 to 200 Knoop)

Purity (Type) and Hardness (Grade) relationship:

Purity Hardness- Type I A, B or C

- Type II B, C or D

- Type III A only

- Class 00 – 0.00002 inch thick, minimum

- Class 0 – 0.00003 inch thick, minimum

- Class 1 – 0.00005 inch thick, minimum

- Class 2 – 0.00010 inch thick, minimum

- Class 3 – 0.00020 inch thick, minimum

- Class 4 – 0.00030 inch thick, minimum

- Class 5 – 0.00050 inch thick, minimum

- Class 6 – 0.00150 inch thick, minimum

Gold Plating Services to ASTM B488-01:

- Type I: 99.7% pure gold with a hardness ranging from A (90 HK25 max) to C (130-200 HK25).

- Type II: 99.0% pure gold often referred to as hard gold with a hardness ranging from B (91-129 KH25) to D (> 200 HK25).

- Type III: 99.9% pure gold often referred to as soft gold with a hardness of A only (90 HK25 Max).

Code:

- Code A: 90 HK25 Maximum

- Code B: 91-129 HK25

- Code C: 130-200 HK25

- Code D: > 200 HK25

Relationship Between Purity and Hardness

Type Code- I A, B and C

- II B, C and D

- III A Only

- 0.25 0.25

- 0.50 0.50

- 0.75 0.75

- 1.0 1.0

- 1.25 1.25

- 2.5 2.5

- 5 5.0

Purity (Type) and Hardness (Grade) relationship:

Purity Hardness- Type I A, B or C

- Type II B, C or D

- Type III A only

- Class 00 – 0.00002 inch thick, minimum

- Class 0 – 0.00003 inch thick, minimum

- Class 1 – 0.00005 inch thick, minimum

- Class 2 – 0.00010 inch thick, minimum

- Class 3 – 0.00020 inch thick, minimum

- Class 4 – 0.00030 inch thick, minimum

- Class 5 – 0.00050 inch thick, minimum

- Class 6 – 0.00150 inch thick, minimum